Home > Sewage disposal >

Sewage disposal

Medical wastewater integrated equipment

Author:hngoob Renew time:2020-02-22

Medical wastewater integrated equipment

This equipment adopts the advanced international biological treatment process, on the basis of summarizing the operation experience of domestic sewage treatment devices at home and abroad, and combining with our own research results and engineering practice, a geographically configurable set of organic wastewater treatment device is designed, which integrates the removal of BOD5, COD and NH3-n. it has the advantages of stable and reliable technical performance, good treatment effect, low investment, automatic operation, convenient maintenance and operation, no floor area, no building, no heating and heat preservation, etc. Flowers and plants can be planted on the ground without affecting the surrounding environment. The equipment is suitable for the treatment and reuse of domestic sewage such as residential quarters, villages, villages and towns, office buildings, shopping malls, hotels, restaurants, sanatoriums, schools, hospitals, expressways, railways, factories, mines, tourist attractions and similar small and medium-sized industrial organic wastewater such as slaughtering, aquatic product processing and food. The equipment treats sewage and the water quality reaches the national discharge standard. Our company can provide reclaimed water reuse equipment at the same time according to user requirements.

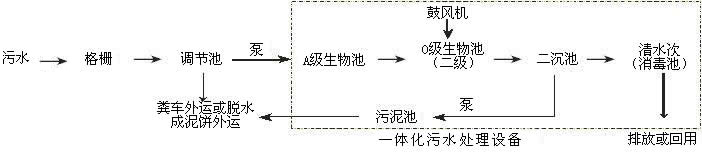

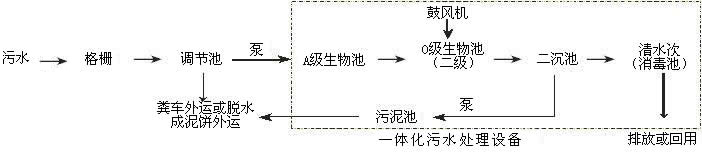

II. Process Description:

III, product characteristics:

1, buried under the surface, the surface above the equipment can be used as green or other land, do not need to build houses and heating, heat preservation. The two-stage biological contact oxidation processes all adopt plug-flow biological contact oxidation, and the treatment effect is better than that of completely mixed or two-stage series completely mixed biological contact oxidation tanks. Compared with activated sludge tank, it has small volume, strong applicability to water quality, good impact load resistance, stable effluent quality and no sludge bulking.

2.A novel elastic three-dimensional filler is adopted in the tank, the specific surface area is large, microorganisms are easy to film and demould, the organic matter removal rate is high under the same organic matter loading condition, and the solubility of oxygen in air in water can be improved.

3. The bio-contact oxidation method is adopted in the biochemical tank. The volume load of the filler is relatively low, the microorganism is in its own oxidation stage, and the sludge yield is low. The sludge only needs to be discharged once every three months (90 days) (the sludge cake is sucked or dehydrated by a dung truck and transported outside).

4. The deodorization method of the geographic domestic sewage treatment equipment is not only conventional high-altitude exhaust, but also soil deodorization measures.

5. The whole equipment processing system is equipped with a full-automatic electrical control system and an equipment failure alarm system. The operation is safe and reliable. Normally, there is no need for special personnel to manage the system.

Only timely maintenance and maintenance of the equipment are required.

IV. Usage:

1. Able to treat comprehensive wastewater from living system and similar organic wastewater;

2. Adopt carbon steel anti-corrosion, stainless steel and glass fiber reinforced plastic structure, with excellent characteristics of corrosion resistance and aging resistance, with service life of more than 50 years.

3. The complete set of equipment is simple to construct and easy to operate. All mechanical equipment is automatically controlled. All equipment can be installed on the ground surface.

V scope of application:

1, hotels, restaurants, nursing homes, hospitals;

2, residential areas, villages and towns;

3. Stations, harbors, docks and ships;

4, factories, mines, tourist attractions, scenic spots;

5. Various industrial organic wastewater similar to domestic wastewater.

VI. Schematic Diagram of Process Flow

vII, under different conditions of equipment processing water (m3/h)

VIII, installation foundation, use and maintenance:

1. Foundation; If WSZ series equipment is placed above the terrace, only a concrete terrace with the same appearance as the equipment needs to be prepared as the foundation. The bearing capacity of foundation must be greater than 4T/m2, and it also requires level and smoothness. If the equipment is buried below the terrace, the foundation elevation must be less than or equal to the equipment elevation to ensure rain and no ponding. The foundation is generally plain concrete (reinforcement depends on local geological conditions).

2. Installation: According to the installation drawing, the boxes shall be in place in sequence. The positions and directions of the boxes shall not be misplaced. The spacing between them shall be accurate and the pipes shall be connected properly. Fill the equipment with clean water, check whether there is any leakage in each pipeline, if there is no leakage, cover the soil around the box until the equipment inspection hole is reached, and level off the ground. Connect the control line of the electric control box to the water pump, connect the electric control box to the power supply, and pay attention to the steering of the fan and motor when connecting the wires, which must be in the same direction as the fan.

IX, equipment structure:

All pipes of the equipment shall be PVC pipes or stainless steel pipes, and the connection between pipes shall be welded with PVC adhesive or stainless steel. The filler adopts suspended biological filler as biological carrier, which has large biomass, easy film formation, no ball formation and specific blockage.

X. Main Parameters:

II. Process Description:

III, product characteristics:

1, buried under the surface, the surface above the equipment can be used as green or other land, do not need to build houses and heating, heat preservation. The two-stage biological contact oxidation processes all adopt plug-flow biological contact oxidation, and the treatment effect is better than that of completely mixed or two-stage series completely mixed biological contact oxidation tanks. Compared with activated sludge tank, it has small volume, strong applicability to water quality, good impact load resistance, stable effluent quality and no sludge bulking.

2.A novel elastic three-dimensional filler is adopted in the tank, the specific surface area is large, microorganisms are easy to film and demould, the organic matter removal rate is high under the same organic matter loading condition, and the solubility of oxygen in air in water can be improved.

3. The bio-contact oxidation method is adopted in the biochemical tank. The volume load of the filler is relatively low, the microorganism is in its own oxidation stage, and the sludge yield is low. The sludge only needs to be discharged once every three months (90 days) (the sludge cake is sucked or dehydrated by a dung truck and transported outside).

4. The deodorization method of the geographic domestic sewage treatment equipment is not only conventional high-altitude exhaust, but also soil deodorization measures.

5. The whole equipment processing system is equipped with a full-automatic electrical control system and an equipment failure alarm system. The operation is safe and reliable. Normally, there is no need for special personnel to manage the system.

Only timely maintenance and maintenance of the equipment are required.

IV. Usage:

1. Able to treat comprehensive wastewater from living system and similar organic wastewater;

2. Adopt carbon steel anti-corrosion, stainless steel and glass fiber reinforced plastic structure, with excellent characteristics of corrosion resistance and aging resistance, with service life of more than 50 years.

3. The complete set of equipment is simple to construct and easy to operate. All mechanical equipment is automatically controlled. All equipment can be installed on the ground surface.

V scope of application:

1, hotels, restaurants, nursing homes, hospitals;

2, residential areas, villages and towns;

3. Stations, harbors, docks and ships;

4, factories, mines, tourist attractions, scenic spots;

5. Various industrial organic wastewater similar to domestic wastewater.

VI. Schematic Diagram of Process Flow

vII, under different conditions of equipment processing water (m3/h)

| Intake BOD(mg/L) | 200 | 300 | 400 | 500 | 300 | 400 | 500 | 600 | 400 | 500 | 600 | 700 | |

| EffluentBOD(mg/L) | 20 | 20 | 20 | 20 | 30 | 30 | 30 | 30 | 60 | 60 | 60 | 60 | |

| WSZ—1 | 处理水量 | 2 | 1.5 | 1 | 0.8 | 2 | 1.5 | 1 | 0.8 | 1.3 | 0.9 | 0.8 | 0.8 |

| WSZ—2 | 3 | 2.5 | 2 | 1.5 | 3 | 2.5 | 2 | 1.5 | 2.4 | 1.8 | 1.5 | 1.5 | |

| WSZ—5 | 6 | 5 | 4 | 3 | 5.5 | 4.5 | 3.5 | 2.5 | 4.8 | 3.6 | 3 | 2.5 | |

| WSZ—10 | 12 | 10 | 8 | 6 | 11 | 9 | 7 | 5 | 9.5 | 7.6 | 6 | 5 | |

VIII, installation foundation, use and maintenance:

1. Foundation; If WSZ series equipment is placed above the terrace, only a concrete terrace with the same appearance as the equipment needs to be prepared as the foundation. The bearing capacity of foundation must be greater than 4T/m2, and it also requires level and smoothness. If the equipment is buried below the terrace, the foundation elevation must be less than or equal to the equipment elevation to ensure rain and no ponding. The foundation is generally plain concrete (reinforcement depends on local geological conditions).

2. Installation: According to the installation drawing, the boxes shall be in place in sequence. The positions and directions of the boxes shall not be misplaced. The spacing between them shall be accurate and the pipes shall be connected properly. Fill the equipment with clean water, check whether there is any leakage in each pipeline, if there is no leakage, cover the soil around the box until the equipment inspection hole is reached, and level off the ground. Connect the control line of the electric control box to the water pump, connect the electric control box to the power supply, and pay attention to the steering of the fan and motor when connecting the wires, which must be in the same direction as the fan.

IX, equipment structure:

All pipes of the equipment shall be PVC pipes or stainless steel pipes, and the connection between pipes shall be welded with PVC adhesive or stainless steel. The filler adopts suspended biological filler as biological carrier, which has large biomass, easy film formation, no ball formation and specific blockage.

X. Main Parameters:

|

Project/model |

WSZ-1 | WSZ- | WSZ- | WSZ- | WSZ- | WSZ- | WSZ- | WSZ- | WSZ- | WSZ- |

| Treatment capacitym³/h | 1 | 3 | 5 | 7.5 | 10 | 15 | 20 | 30 | 40 | 50 |

| Number | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 4 | 4 |

| Sludge adsorption and primary sedimentation tank Pool | 1.8 | 5.5 | 9 | 14 | 18 | 27 | 36 | 50 | 82 | 100 |

|

Contact oxidation cell (m³) |

5.0 | 14.5 | 24 | 36 | 44 | 63 | 83 | 130 | 170 | 200 |

|

Surface load of secondary sedimentation tank (m³/m²h) |

1.2 | 1.3 | 1.3 | 1.3 | 1.2 | 1.2 | 1.5 | 1.5 | 1.5 | 1.6 |

| Disinfection pool(m³) | 0.6 | 1.8 | 2.8 | 4 | 5.5 | 8 | 10 | 15 | 20 | 25 |

| fan model | HC-25IS | HC-30IS | HC-50C | HC-50IS | HC-60IS | HC-80S | HC-100S | HC1-100S | HC-100S | HC-100S |

| fan powerkw) | 0.4 | 0.75 | 1.5 | 2.2 | 2.2 | 3.7 | 5.5 | 5.5 | 5.5×2 | 5.5×2 |

| Number | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 |

| pump model | AS10-2CB | AS16-CB | AS30- 2CB | |||||||

| pump powerkw | 1.0 | 1.6 | 2.9 | |||||||

| Maximum weight(t) | 5 | 6 | 7 | 10 | 8 | 10 | 10.5 | 10.5 | 10.5 | 12 |

| Total weight of equipment(t) | 5.5 | 6.5 | 8 | 11 | 17 | 20 | 21 | 29 | 38 | 42 |

| Floor space(m²) | 6 | 14 | 20 | 30 | 50 | 65 | 75 | 115 | 155 | 185 |

Note: The above parameters and equipment dimensions are for reference only. Please refer to the actual parameters and drawing dimensions of our company for design.